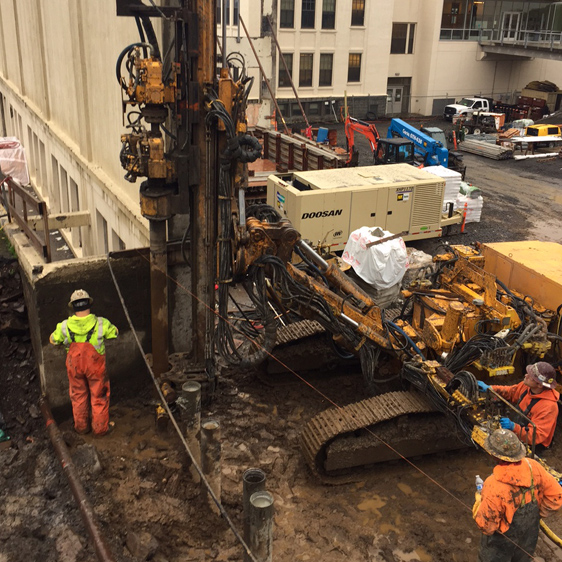

Location: Oak Harbor, WA

Project Partner: Hoffman Construction

Challenge: Installation of water-tight shoring for excavation below the water table and high capacity micropiles.

Overview: Condon-Johnson was contracted to design and install the sheet pile and tieback shoring along with 306 micropiles with design loads over 350 kips.

Results: Condon-Johnson was able to successfully design and install a shoring system below the water table utilizing sheet piles for ground water cutoff and tiebacks. The tiebacks were able to be installed and locked off using a specialized water sealing system which mitigated ground loss during and after the tieback was installed. At the base of the excavation, over 300 micropiles were installed to support the new water facility.

PROJECTS

Oak Harbor Clean Water Facility

Tacoma Micro Tunneling Shaft Bottom Seals Jet Grouting

Location: Port of Tacoma, WA

Project Partner: Frank Coluccio Construction Company (FCC)

Challenge: Provide a watertight bottom seal to four deep excavations to prevent the risk of dewatering moving contaminates from a nearby superfund site. Previously installed CFA columns to support the future pipeline provided an added obstacle to creating a watertight bottom seal.

Overview: Condon-Johnson was contracted by FCC to install jet grout bottom seals in four different sheet pile shored excavations. The plugs were to provide excavation support and ground water control for micro tunneling operations.

Results: Condon-Johnson used a combination of 6 foot and 8 foot diameter columns to complete the work. The jet grout plugs provided the excavation support and ground water control required for the micro tunneling operations. The installed jet grout had unconfined compressive strengths greater than 150-psi at 28 days and a unit weight of 114-pcf. Ground water infiltration through each bottom seal was limited to less than 10-gpm.

Project Partner: Frank Coluccio Construction Company (FCC)

Challenge: Provide a watertight bottom seal to four deep excavations to prevent the risk of dewatering moving contaminates from a nearby superfund site. Previously installed CFA columns to support the future pipeline provided an added obstacle to creating a watertight bottom seal.

Overview: Condon-Johnson was contracted by FCC to install jet grout bottom seals in four different sheet pile shored excavations. The plugs were to provide excavation support and ground water control for micro tunneling operations.

Results: Condon-Johnson used a combination of 6 foot and 8 foot diameter columns to complete the work. The jet grout plugs provided the excavation support and ground water control required for the micro tunneling operations. The installed jet grout had unconfined compressive strengths greater than 150-psi at 28 days and a unit weight of 114-pcf. Ground water infiltration through each bottom seal was limited to less than 10-gpm.

Tabor Dam

Location: Saint Ignatius, MT

Project Partner: N/A

Challenge: Dewatering, core drilling and void grouting from inside a limited access outlet tunnel for a dam in the middle of winter in Montana.

Overview: Condon-Johnson was contracted as the General Contractor to dewater over 400 million gallons of water from the Saint Mary’s Reservoir and perform void grouting from over 500 feet inside of a four foot wide by six foot tall tunnel.

Results: Condon-Johnson was able to successfully overcome temperatures as low as 30 degrees below zero while dewatering the reservoir to 6-feet below the invert of the tunnel. It was then a race against time to complete the drilling and void grouting while the reservoir inched closer to the mouth of the tunnel. All drilling and grouting was completed ahead of schedule and at a cost savings to the Owner.

Project Partner: N/A

Challenge: Dewatering, core drilling and void grouting from inside a limited access outlet tunnel for a dam in the middle of winter in Montana.

Overview: Condon-Johnson was contracted as the General Contractor to dewater over 400 million gallons of water from the Saint Mary’s Reservoir and perform void grouting from over 500 feet inside of a four foot wide by six foot tall tunnel.

Results: Condon-Johnson was able to successfully overcome temperatures as low as 30 degrees below zero while dewatering the reservoir to 6-feet below the invert of the tunnel. It was then a race against time to complete the drilling and void grouting while the reservoir inched closer to the mouth of the tunnel. All drilling and grouting was completed ahead of schedule and at a cost savings to the Owner.

Long Beach Main Pumping Plant

Location: Long Beach, CA

Project Partner: Steve P. Rados

Challenge: Construct water-tight shoring for the new Long Beach Main Pumping Plant.

Overview: Condon-Johnson was contracted to design and construct water-tight shoring for the new subterranean pump station.

Results: Condon-Johnson utilized internally braced, soil-mixed shoring and a tied-down, jet grout bottom seal to provide completely water-tight shoring that allowed for excavation to advance approximately 38 feet below the water table without the need for dewatering. Triple-axis soil mixing was performed with an ABI 18-24. Jet grouting and the tiedowns were drilled with a Klemm 3012.

Project Partner: Steve P. Rados

Challenge: Construct water-tight shoring for the new Long Beach Main Pumping Plant.

Overview: Condon-Johnson was contracted to design and construct water-tight shoring for the new subterranean pump station.

Results: Condon-Johnson utilized internally braced, soil-mixed shoring and a tied-down, jet grout bottom seal to provide completely water-tight shoring that allowed for excavation to advance approximately 38 feet below the water table without the need for dewatering. Triple-axis soil mixing was performed with an ABI 18-24. Jet grouting and the tiedowns were drilled with a Klemm 3012.

Central Subway Tunneling

Location: San Francisco, CA

Project Partner: Nicholson Construction Co.

Challenge: Settlement mitigation and compensation for a verity of mid- and high-rise buildings as well as BART & MUNI tunnels in downtown San Francisco during tunneling excavations underneath.

Overview: Condon-Johnson was contracted to install over 20,000 linear feet of sub-horizontal Manchette Tube System (TAM’s) in close proximity of sensitive structures such as existing BART and MUNI tunnels underneath Market Street Throughout this operation, CJA injected over 75,000 gallons of grout during pre-conditioning and active compensation grouting. CJA utilized advanced alignment tools and downhole survey methods to ensure drilling accuracy in vicinity of existing subsurface structures.

Results: By utilizing skilled workforces, advanced equipment, cutting-edge drilling, surveying, and grouting techniques, Condon-Johnson managed to successfully complete this grouting work, resulting in minimal settlement of existing structures due to tunneling activities as well as creating a controlled heave to balance any existing non-uniform settlements in targeted structures from before.

Project Partner: Nicholson Construction Co.

Challenge: Settlement mitigation and compensation for a verity of mid- and high-rise buildings as well as BART & MUNI tunnels in downtown San Francisco during tunneling excavations underneath.

Overview: Condon-Johnson was contracted to install over 20,000 linear feet of sub-horizontal Manchette Tube System (TAM’s) in close proximity of sensitive structures such as existing BART and MUNI tunnels underneath Market Street Throughout this operation, CJA injected over 75,000 gallons of grout during pre-conditioning and active compensation grouting. CJA utilized advanced alignment tools and downhole survey methods to ensure drilling accuracy in vicinity of existing subsurface structures.

Results: By utilizing skilled workforces, advanced equipment, cutting-edge drilling, surveying, and grouting techniques, Condon-Johnson managed to successfully complete this grouting work, resulting in minimal settlement of existing structures due to tunneling activities as well as creating a controlled heave to balance any existing non-uniform settlements in targeted structures from before.

Centinella West

Location: Los Angeles, CA

Project Partner: Skanska USA Civil

Challenge: Installation of compaction grouting with confined access, overhead restrictions and limited work schedule.

Overview: A newly constructed embankment exhibited significant settlement. A geotechnical engineer designed a compaction grout program consisting of 198 points along each side of a railroad embankment. Each side of the embankment consisted of 100 vertical points, 49 – 15 degree angled points and 49 – 30 degree angled points for a total quantity of 396 compaction grout points to depths of 20 feet each. Additionally, work hours were initially limited to train off-hours (night work).

Results: Condon-Johnson installed a test program at night and settlements were measured during the test program. The movement was within tolerance and Condon-Johnson was allowed to change work to day shifts while the metro train was in operation. Condon-Johnson utilized a low head room TEI drill and worked off of a wood platform constructed on top with the rail ties on one side of the embankment and on a limited width bike path on the other side of the embankment. Condon-Johnson successfully drilled 8,293 LF and injected 12,135 CF of compaction grout ahead of schedule.

Project Partner: Skanska USA Civil

Challenge: Installation of compaction grouting with confined access, overhead restrictions and limited work schedule.

Overview: A newly constructed embankment exhibited significant settlement. A geotechnical engineer designed a compaction grout program consisting of 198 points along each side of a railroad embankment. Each side of the embankment consisted of 100 vertical points, 49 – 15 degree angled points and 49 – 30 degree angled points for a total quantity of 396 compaction grout points to depths of 20 feet each. Additionally, work hours were initially limited to train off-hours (night work).

Results: Condon-Johnson installed a test program at night and settlements were measured during the test program. The movement was within tolerance and Condon-Johnson was allowed to change work to day shifts while the metro train was in operation. Condon-Johnson utilized a low head room TEI drill and worked off of a wood platform constructed on top with the rail ties on one side of the embankment and on a limited width bike path on the other side of the embankment. Condon-Johnson successfully drilled 8,293 LF and injected 12,135 CF of compaction grout ahead of schedule.

Calaveras Dam Replacement Project

Location: Sunol, CA

Project Partner: Dragados-Flatiron-Sukut JV

Challenge: Plan and execute the foundation drilling and grouting scope in a sequence to avoid delay to the critical path earth work activities.

Overview: Condon-Johnson was contracted to complete the foundation drilling and grouting scope downstream of the existing dam to minimize seepage through the underlying bedrock of the future dam. The grout utilized was a suite of cement-based stable high-mobility grouts with varying viscosities. All injection and permeation testing was monitored and recorded via Condon-Johnson’s custom real-time computer monitoring system.

Results: Through collaborative efforts, the design and construction teams, including the General Contractor, were able to work closely to devise an effective plan to minimize the foundation drilling and grouting scope’s duration on the critical path for the new dam construction. Although some procedures were not typical for dam foundation grouting, the performance goals and traditional grouting requirements were consistently met. Four different types of drill rigs were utilized to overcome the challenging access.

Project Partner: Dragados-Flatiron-Sukut JV

Challenge: Plan and execute the foundation drilling and grouting scope in a sequence to avoid delay to the critical path earth work activities.

Overview: Condon-Johnson was contracted to complete the foundation drilling and grouting scope downstream of the existing dam to minimize seepage through the underlying bedrock of the future dam. The grout utilized was a suite of cement-based stable high-mobility grouts with varying viscosities. All injection and permeation testing was monitored and recorded via Condon-Johnson’s custom real-time computer monitoring system.

Results: Through collaborative efforts, the design and construction teams, including the General Contractor, were able to work closely to devise an effective plan to minimize the foundation drilling and grouting scope’s duration on the critical path for the new dam construction. Although some procedures were not typical for dam foundation grouting, the performance goals and traditional grouting requirements were consistently met. Four different types of drill rigs were utilized to overcome the challenging access.

Rigid Inclusions for a Natural Gas Facility

Location: Puget Sound Area, WA

Project Partner: Private Energy Company (Owner)

Challenge: Reinforce liquefiable soils up to a maximum depth of 100 feet to mitigate the effects of liquefaction and lateral spread. Provide a minimum of 4500-psf bearing capacity for future mechanical, piping, and tank systems. In addition to native silts and sands, the site soil profile included near surface debris that posed an obstacle to penetration and maintaining the specified verticality tolerance.

Overview: Condon-Johnson contracted directly with a private energy company (Owner) to install Rigid Inclusions for construction of a new natural gas facility. Ground Improvement using Rigid Inclusions was used to mitigate the effects of both seismically induced soil liquefaction settlement and lateral spreading. Moreover, the Rigid Inclusions were designed to reduce short and long term static consolidation settlements for the new natural gas facility.

Results: Condon-Johnson conducted a static settlement test program at the beginning of the project to verify the project design parameters. Upon completion of the test program, Condon-Johnson completed the work by installing over 2,000 3-foot diameter Rigid Inclusions up to 100 feet in length. Over 50,000-cyds of concrete were placed, documented and successfully tested. The Rigid Inclusion ground improvement system was installed on schedule and on budget using Bauer BG-46 and BG-39 drill rigs.

Project Partner: Private Energy Company (Owner)

Challenge: Reinforce liquefiable soils up to a maximum depth of 100 feet to mitigate the effects of liquefaction and lateral spread. Provide a minimum of 4500-psf bearing capacity for future mechanical, piping, and tank systems. In addition to native silts and sands, the site soil profile included near surface debris that posed an obstacle to penetration and maintaining the specified verticality tolerance.

Overview: Condon-Johnson contracted directly with a private energy company (Owner) to install Rigid Inclusions for construction of a new natural gas facility. Ground Improvement using Rigid Inclusions was used to mitigate the effects of both seismically induced soil liquefaction settlement and lateral spreading. Moreover, the Rigid Inclusions were designed to reduce short and long term static consolidation settlements for the new natural gas facility.

Results: Condon-Johnson conducted a static settlement test program at the beginning of the project to verify the project design parameters. Upon completion of the test program, Condon-Johnson completed the work by installing over 2,000 3-foot diameter Rigid Inclusions up to 100 feet in length. Over 50,000-cyds of concrete were placed, documented and successfully tested. The Rigid Inclusion ground improvement system was installed on schedule and on budget using Bauer BG-46 and BG-39 drill rigs.

Pier 4 Phase 2 Reconfiguration

Location: Tacoma, WA

Project Partner: Manson Construction Co.

Challenge: Installation of in-water stone columns which were located in the active Blair Waterway

Overview: Condon-Johnson was contracted to install over 1,100 42-inch diameter stone columns for liquefaction mitigation at the Port of Tacoma.

Results: Condon-Johnson was able to successfully install the dry-bottom feed stone columns ahead of schedule and at a cost savings to the Owner. Installation of the stone columns in the Blair Waterway were met with several challenges ranging from tidal influence to previously driven wood pile obstructions to coordinating installation in an active shipping waterway.

Project Partner: Manson Construction Co.

Challenge: Installation of in-water stone columns which were located in the active Blair Waterway

Overview: Condon-Johnson was contracted to install over 1,100 42-inch diameter stone columns for liquefaction mitigation at the Port of Tacoma.

Results: Condon-Johnson was able to successfully install the dry-bottom feed stone columns ahead of schedule and at a cost savings to the Owner. Installation of the stone columns in the Blair Waterway were met with several challenges ranging from tidal influence to previously driven wood pile obstructions to coordinating installation in an active shipping waterway.

McHenry Bridge Replacement – Ground Improvement Stone Columns

Location: Escalon, CA

Project Partner: Myers and Sons Construction, LP

Challenge: The installation of ground improvement stone columns at a congested jobsite to be completed in two phases.

Overview: Condon-Johnson was contracted to install drilled shafts, driven piles, and stone column ground improvement for the McHenry Bridge replacement project. The design goal of the stone columns were to mitigate the liquefaction and lateral spread potential of the upper loose sand that lies adjacent to the Stanislaus River and in which the piles are embedded.

Results: The Condon-Johnson crews dedicated to the three scopes of work – drilled shafts, driven piles, and ground improvement – worked closely together to plan and sequence the work to complete it in a manner that was most beneficial to the overall project. Packaging the three scopes together allowed the General Contractor to focus their efforts on the bridge demolition and construction while relying on Condon-Johnson to execute all three foundation scopes simultaneously.

Project Partner: Myers and Sons Construction, LP

Challenge: The installation of ground improvement stone columns at a congested jobsite to be completed in two phases.

Overview: Condon-Johnson was contracted to install drilled shafts, driven piles, and stone column ground improvement for the McHenry Bridge replacement project. The design goal of the stone columns were to mitigate the liquefaction and lateral spread potential of the upper loose sand that lies adjacent to the Stanislaus River and in which the piles are embedded.

Results: The Condon-Johnson crews dedicated to the three scopes of work – drilled shafts, driven piles, and ground improvement – worked closely together to plan and sequence the work to complete it in a manner that was most beneficial to the overall project. Packaging the three scopes together allowed the General Contractor to focus their efforts on the bridge demolition and construction while relying on Condon-Johnson to execute all three foundation scopes simultaneously.

Jordan High School-Demo, Deep Soil Mixing

Location: Long Beach, CA

Project Partner: Long Beach Unified School District

Challenge: Installation of cement deep soil mixing with tight tolerances and within project schedule

Overview: To limit the anticipated total and differential settlement due to structural loads and liquefaction potential below two new proposed classroom buildings M & N, Division of State Architects (DSA) designed a Cement Deep Soil Mixing (CDSM) program. Although designed by DSA, Condon-Johnson was required to conduct additional soil investigation and trial batch testing on retrieved soil samples to confirm that DSA’s design would meet the performance criteria. Additional scopes included spoils export, demolition of existing buildings and earthwork.

Results: Condon-Johnson conducted analysis and submitted the results. Condon-Johnson intended on installing the soil mixing with triple axis augers, however, the owner’s geotechnical engineer did not agree with the grid pattern and the double axis mixing with intermittent single axis columns were installed. Condon-Johnson installed 1,490 double axis panels (3 foot diameter) and 66 single axis columns (3 foot diamater) to treatment depths of 32.5 feet below working grade. The dense soil required each location to be pre-drilled full depth. The project was completed within schedule.

Project Partner: Long Beach Unified School District

Challenge: Installation of cement deep soil mixing with tight tolerances and within project schedule

Overview: To limit the anticipated total and differential settlement due to structural loads and liquefaction potential below two new proposed classroom buildings M & N, Division of State Architects (DSA) designed a Cement Deep Soil Mixing (CDSM) program. Although designed by DSA, Condon-Johnson was required to conduct additional soil investigation and trial batch testing on retrieved soil samples to confirm that DSA’s design would meet the performance criteria. Additional scopes included spoils export, demolition of existing buildings and earthwork.

Results: Condon-Johnson conducted analysis and submitted the results. Condon-Johnson intended on installing the soil mixing with triple axis augers, however, the owner’s geotechnical engineer did not agree with the grid pattern and the double axis mixing with intermittent single axis columns were installed. Condon-Johnson installed 1,490 double axis panels (3 foot diameter) and 66 single axis columns (3 foot diamater) to treatment depths of 32.5 feet below working grade. The dense soil required each location to be pre-drilled full depth. The project was completed within schedule.

Horse Creek Ridge Phase 2

Location: Fallbrook, CA

Project Partner: Mesa General Engineering

Challenge: Shoring installation of a lift station for a new sub-division being constructed in Fallbrook. The lift station location was shown to be in an area susceptible to seismic settlement.

Overview: Condon-Johnson was contracted to design, construct and excavate a water-tight braced sheet piling shoring system for the lift station and wet well, as well as stone columns to mitigate liquefaction induced settlements.

Results: Condon-Johnson installed 30 foot long sheet piles along the perimeter of the lift station, 34 foot long sheet piles along the perimeter of the wet well, excavated the lift station 8.5 foot below grade and excavated the wet well to a depth of 24 feet, and placed a tied down seal slab in the wet well. Additionally, Condon-Johnson installed 116 ea. 36-inch diameter bottom feed stone columns installed to a depth of 55 feet below existing grade utilizing an 8 foot square pattern.

Project Partner: Mesa General Engineering

Challenge: Shoring installation of a lift station for a new sub-division being constructed in Fallbrook. The lift station location was shown to be in an area susceptible to seismic settlement.

Overview: Condon-Johnson was contracted to design, construct and excavate a water-tight braced sheet piling shoring system for the lift station and wet well, as well as stone columns to mitigate liquefaction induced settlements.

Results: Condon-Johnson installed 30 foot long sheet piles along the perimeter of the lift station, 34 foot long sheet piles along the perimeter of the wet well, excavated the lift station 8.5 foot below grade and excavated the wet well to a depth of 24 feet, and placed a tied down seal slab in the wet well. Additionally, Condon-Johnson installed 116 ea. 36-inch diameter bottom feed stone columns installed to a depth of 55 feet below existing grade utilizing an 8 foot square pattern.

Cushman No. 1 Spillway – Core Wall Extension

Location: Hoodsport, WA

Project Partner: Tacoma Public Utilities-Tacoma Power

Challenge: In the vicinity of Spillway 1 at Lake Cushman, it was observed that water from within the lake was seeping through the earth dams surrounding it. Further sub-surface investigations within the earth dams confirmed that there was some loss of material within due to this leakage. The subsurface investigations indicated that the overburden was mainly of recessional outwash composed of GM, SP-SM and SP type material followed by a recessional lacustrine deposit layer of mainly ML material down to the lodgment till. To prevent further loss of material and water from within the lake, it was decided to extend the existing core-wall using the soil mixing technique. The soil mixed panels were to be installed down to 5 feet within the glacial till. The design requirement for the soil mixed material was a permeability of 1 x 10-6 cm/sec and strength in the range of 50 psi – 100 psi at 14-days.

Overview: Condon-Johnson was contracted to perform a horizontal extension of the soil-cement core wall by 273 feet horizontally, 2.8 feet thick and up to 75 feet in depth.

Results: Condon-Johnson carried out the core-wall extension using cutter soil mixed panels of dimensions 2.8 feet x 9.2 feet with a 1 foot overlap. The contractor developed mix design consisted of bentonite slurry and cement grout to provide a soil mixed material capable of meeting the design requirements and successfully cut off the seepage that had been occurring.

Project Partner: Tacoma Public Utilities-Tacoma Power

Challenge: In the vicinity of Spillway 1 at Lake Cushman, it was observed that water from within the lake was seeping through the earth dams surrounding it. Further sub-surface investigations within the earth dams confirmed that there was some loss of material within due to this leakage. The subsurface investigations indicated that the overburden was mainly of recessional outwash composed of GM, SP-SM and SP type material followed by a recessional lacustrine deposit layer of mainly ML material down to the lodgment till. To prevent further loss of material and water from within the lake, it was decided to extend the existing core-wall using the soil mixing technique. The soil mixed panels were to be installed down to 5 feet within the glacial till. The design requirement for the soil mixed material was a permeability of 1 x 10-6 cm/sec and strength in the range of 50 psi – 100 psi at 14-days.

Overview: Condon-Johnson was contracted to perform a horizontal extension of the soil-cement core wall by 273 feet horizontally, 2.8 feet thick and up to 75 feet in depth.

Results: Condon-Johnson carried out the core-wall extension using cutter soil mixed panels of dimensions 2.8 feet x 9.2 feet with a 1 foot overlap. The contractor developed mix design consisted of bentonite slurry and cement grout to provide a soil mixed material capable of meeting the design requirements and successfully cut off the seepage that had been occurring.

Purple Line Extension Project, Section 1

Location: Los Angeles, CA

Project Partner: Skanska-Traylor-Shea, A Joint Venture

Challenge:

Limited access work zones adjacent to live vehicle and pedestrian traffic posed challenges for the installation of the 95 foot 20,000 plus pound soldier pile beams. Drilling through the tar impacted sands at the Fairfax Station resulted in difficulties unique to that specific area of the La Brea Tar Pits. In one area at the Fairfax station, Condon-Johnson routinely cored through 5 levels of existing abandoned bar anchors at every soldier pile location.

Overview:

Condon-Johnson was contracted by Skanska-Traylor-Shea to perform the soldier pile installation as part of the support of excavation on the Purple Line Extension Project, Section 1. Condon-Johnson installed 1,545 each soldier piles drilling approximately 120,000 feet and hoisting over 23 million pounds of steel for the shoring at the three new stations and tie in. Condon-Johnson began installation at the La Brea station in December 2015, the Fairfax station in August 2016, the La Cienega station in March 2017 and completed the Western tie in shaft in February 2018. Throughout this four mile stretch along Wilshire Boulevard in Los Angeles, Condon-Johnson encountered a variety of challenges from the tar-impacted sand of the La Brea Tar Pits at the Fairfax station to the logistical challenges of heavy civil construction on active and congested city streets.

Results:

Condon-Johnson successfully completed the installation of 1,545 each soldier piles, drilling approximately 120,000 feet and hoisting over 23 million pounds of steel safely without any serious injuries or incidents. Condon-Johnson completed its work on schedule avoiding any delay to the project.

Project Partner: Skanska-Traylor-Shea, A Joint Venture

Challenge:

Limited access work zones adjacent to live vehicle and pedestrian traffic posed challenges for the installation of the 95 foot 20,000 plus pound soldier pile beams. Drilling through the tar impacted sands at the Fairfax Station resulted in difficulties unique to that specific area of the La Brea Tar Pits. In one area at the Fairfax station, Condon-Johnson routinely cored through 5 levels of existing abandoned bar anchors at every soldier pile location.

Overview:

Condon-Johnson was contracted by Skanska-Traylor-Shea to perform the soldier pile installation as part of the support of excavation on the Purple Line Extension Project, Section 1. Condon-Johnson installed 1,545 each soldier piles drilling approximately 120,000 feet and hoisting over 23 million pounds of steel for the shoring at the three new stations and tie in. Condon-Johnson began installation at the La Brea station in December 2015, the Fairfax station in August 2016, the La Cienega station in March 2017 and completed the Western tie in shaft in February 2018. Throughout this four mile stretch along Wilshire Boulevard in Los Angeles, Condon-Johnson encountered a variety of challenges from the tar-impacted sand of the La Brea Tar Pits at the Fairfax station to the logistical challenges of heavy civil construction on active and congested city streets.

Results:

Condon-Johnson successfully completed the installation of 1,545 each soldier piles, drilling approximately 120,000 feet and hoisting over 23 million pounds of steel safely without any serious injuries or incidents. Condon-Johnson completed its work on schedule avoiding any delay to the project.

Patriot Hall Redevelopment

Location: Astoria, OR

Project Partner: P&C Construction

Challenge: Installation of temporary shoring in extremely unstable geologic conditions.

Overview: Condon-Johnson was contracted to install temporary shoring at the Clatsop Community College in Astoria, OR. The site was located on top of an abandoned basalt rock quarry, creating one of the most unique and difficult conditions to shore. Condon-Johnson quickly realized that no traditional shoring system would be feasible in this location due to the loose rubble and presence of 15 foot+ boulders.

Results: Working directly with the engineer, Condon-Johnson developed the concept for a shoring system consisting of pairs of micropiles acting as the main lateral support structural elements of the shoring wall. Multiple rows of tiebacks were drilled between the micropile pairs to support the excavation. A mesh reinforced shotcrete facing was installed and acted as the basement wall form. This project showcased Condon-Johnson’s ability to work closely with engineers to create a constructible design in extremely challenging conditions.

Project Partner: P&C Construction

Challenge: Installation of temporary shoring in extremely unstable geologic conditions.

Overview: Condon-Johnson was contracted to install temporary shoring at the Clatsop Community College in Astoria, OR. The site was located on top of an abandoned basalt rock quarry, creating one of the most unique and difficult conditions to shore. Condon-Johnson quickly realized that no traditional shoring system would be feasible in this location due to the loose rubble and presence of 15 foot+ boulders.

Results: Working directly with the engineer, Condon-Johnson developed the concept for a shoring system consisting of pairs of micropiles acting as the main lateral support structural elements of the shoring wall. Multiple rows of tiebacks were drilled between the micropile pairs to support the excavation. A mesh reinforced shotcrete facing was installed and acted as the basement wall form. This project showcased Condon-Johnson’s ability to work closely with engineers to create a constructible design in extremely challenging conditions.

I-5 North Coast Corridor

Location: San Diego, CA

Project Partner: Flatiron-Skanska-Stacy and Witbeck, A Joint Venture

Challenge: Installation of large diameter piling to 260 feet below grade in a lagoon with a top of permanent steel casing 26 feet below grade.

Overview: Condon-Johnson was contracted to install the drilled shafts for a two phase bridge replacement in San Diego. The first phase widens the freeway, then the original freeway is demolished and rebuilt in the second phase. The project consists of 17 each 10 foot diameter pier piles to 245-260 feet below grade and 44 each 5 foot diameter abutment piles to 165 feet below grade.

Results: Condon-Johnson has successfully completed the first phase of abutment piling (22 each) and will soon complete the west side pier piles (4 each). Numerous installation techniques were utilized to construct piles of unprecedented size and depth. Installation techniques included vibrated casing with an APE 600, oscillator and casing with a Soilmec SR-145 with VRM 250KL drill setup for the 5 foot diameter piles and a Liebherr 895 with Buma C3000G crane setup for the 10 foot diameter piles, and slurry displacement drilling with an IMT AF300 for the CMP top cans and a Bauer BG46 to excavate the rock socket portion of the 10 foot diameter piles.

Project Partner: Flatiron-Skanska-Stacy and Witbeck, A Joint Venture

Challenge: Installation of large diameter piling to 260 feet below grade in a lagoon with a top of permanent steel casing 26 feet below grade.

Overview: Condon-Johnson was contracted to install the drilled shafts for a two phase bridge replacement in San Diego. The first phase widens the freeway, then the original freeway is demolished and rebuilt in the second phase. The project consists of 17 each 10 foot diameter pier piles to 245-260 feet below grade and 44 each 5 foot diameter abutment piles to 165 feet below grade.

Results: Condon-Johnson has successfully completed the first phase of abutment piling (22 each) and will soon complete the west side pier piles (4 each). Numerous installation techniques were utilized to construct piles of unprecedented size and depth. Installation techniques included vibrated casing with an APE 600, oscillator and casing with a Soilmec SR-145 with VRM 250KL drill setup for the 5 foot diameter piles and a Liebherr 895 with Buma C3000G crane setup for the 10 foot diameter piles, and slurry displacement drilling with an IMT AF300 for the CMP top cans and a Bauer BG46 to excavate the rock socket portion of the 10 foot diameter piles.

Jacobs Medical Center

Location: La Jolla, CA

Project Partner: Kitchell Contractors, Inc.

Challenge: Design and construct soil nail and soldier pile shoring for a new hospital, directly adjacent to an existing hospital, under the jurisdiction of OSHPD.

Overview: Condon-Johnson was contracted to design and construct temporary shoring for the basement portion of Jacobs Medical Center.

Results: Condon-Johnson utilized tied-back soldier pile shoring to support the existing hospital under the jurisdiction of OSHPD and soil nail shoring to support the existing parking area that was outside the jurisdiction of OSHPD. Condon-Johnson worked closely with Kitchell and their excavation contractor to complete the shoring and excavation on schedule and without incident.

Project Partner: Kitchell Contractors, Inc.

Challenge: Design and construct soil nail and soldier pile shoring for a new hospital, directly adjacent to an existing hospital, under the jurisdiction of OSHPD.

Overview: Condon-Johnson was contracted to design and construct temporary shoring for the basement portion of Jacobs Medical Center.

Results: Condon-Johnson utilized tied-back soldier pile shoring to support the existing hospital under the jurisdiction of OSHPD and soil nail shoring to support the existing parking area that was outside the jurisdiction of OSHPD. Condon-Johnson worked closely with Kitchell and their excavation contractor to complete the shoring and excavation on schedule and without incident.

Crown Valley Cabot

Location: Laguna Niguel, CA

Project Partner: Mill Creek Residential Trust LLC

Challenge: Building soil nail and soldier pile walls into a steep slope.

Overview: Condon-Johnson was contracted to construct a 34 foot tall soil nail wall with soldier pile return walls on each end to allow for a new residential structure to be built into the existing slope.

Results: The work required close coordination with the general contractor and their excavation contractor to allow for sequenced installation of soldier piles as the soil nail wall and excavation progressed. A Lodril was used to reach the soldier piles that were difficult to access. The wall was finished off with a reinforced shotcrete facing with a rubber float finish.

Project Partner: Mill Creek Residential Trust LLC

Challenge: Building soil nail and soldier pile walls into a steep slope.

Overview: Condon-Johnson was contracted to construct a 34 foot tall soil nail wall with soldier pile return walls on each end to allow for a new residential structure to be built into the existing slope.

Results: The work required close coordination with the general contractor and their excavation contractor to allow for sequenced installation of soldier piles as the soil nail wall and excavation progressed. A Lodril was used to reach the soldier piles that were difficult to access. The wall was finished off with a reinforced shotcrete facing with a rubber float finish.

350 Bush Street

Location: San Francisco, CA

Project Partner: Hathaway Dinwiddie

Challenge: Underpinning and tower shoring to preserve existing 100 year old, unreinforced brick walls.

Overview: Condon-Johnson was contracted to provide Micro piles for support of the tower shoring and new construction, installation of soldier piles and lagging to shore up street frontage on Bush and Pine streets, excavate deep underpinning pits for adjacent unreinforced brick structures, and provide tower shoring for two unreinforced brick walls 100 feet long by 50 feet high.

Results: Condon-Johnson was able to manage this project creatively to achieve a safe and successful completion within Hathaway-Dinwiddie’s construction schedule by providing the right people, equipment, and materials on time.

Project Partner: Hathaway Dinwiddie

Challenge: Underpinning and tower shoring to preserve existing 100 year old, unreinforced brick walls.

Overview: Condon-Johnson was contracted to provide Micro piles for support of the tower shoring and new construction, installation of soldier piles and lagging to shore up street frontage on Bush and Pine streets, excavate deep underpinning pits for adjacent unreinforced brick structures, and provide tower shoring for two unreinforced brick walls 100 feet long by 50 feet high.

Results: Condon-Johnson was able to manage this project creatively to achieve a safe and successful completion within Hathaway-Dinwiddie’s construction schedule by providing the right people, equipment, and materials on time.

San Tomas Square

Location: Santa Clara, CA

Project Partner: Truebeck Construction

Challenge: Design and execution of temporary construction dewatering of a jobsite without affecting external water levels.

Overview: Condon-Johnson was contracted to design and build an impermeable shoring system and dewatering system and install foundation driven piles for a new six story office building with two levels of below grade parking and mechanical rooms.

Results: Condon-Johnson analyzed the site’s subsurface conditions composed of stream deposited alluvium consisting of interbedded layers of clay, silt, sand, and gravel. This soil profile coupled with the building’s unique footprint made for a complex permeation cutoff and dewatering model. Condon-Johnson’s design and execution produced a dewatered construction site without affecting the ground water level outside of the property.

Project Partner: Truebeck Construction

Challenge: Design and execution of temporary construction dewatering of a jobsite without affecting external water levels.

Overview: Condon-Johnson was contracted to design and build an impermeable shoring system and dewatering system and install foundation driven piles for a new six story office building with two levels of below grade parking and mechanical rooms.

Results: Condon-Johnson analyzed the site’s subsurface conditions composed of stream deposited alluvium consisting of interbedded layers of clay, silt, sand, and gravel. This soil profile coupled with the building’s unique footprint made for a complex permeation cutoff and dewatering model. Condon-Johnson’s design and execution produced a dewatered construction site without affecting the ground water level outside of the property.

Moscone West Expansion

Location: San Francisco, CA

Project Partner: Subsurface Environmental Inc.

Challenge: Construction Dewatering

Overview: Condon-Johnson was contracted to install the temporary shoring and provide dewatering for the Moscone West Convention Center excavation.

Results: Condon-Johnson designed and installed the dewatering system to allow excavation of a 30 foot deep excavation of a 500 foot by 300 foot site. The scope included installing 30 dewatering wells, installation and maintenance of pumps, associated piping, back-up generator, and sediment tanks. The system was maintained for 19 months and then removed.

Project Partner: Subsurface Environmental Inc.

Challenge: Construction Dewatering

Overview: Condon-Johnson was contracted to install the temporary shoring and provide dewatering for the Moscone West Convention Center excavation.

Results: Condon-Johnson designed and installed the dewatering system to allow excavation of a 30 foot deep excavation of a 500 foot by 300 foot site. The scope included installing 30 dewatering wells, installation and maintenance of pumps, associated piping, back-up generator, and sediment tanks. The system was maintained for 19 months and then removed.

Genesee CSO Reduction Project

Location: Seattle, WA

Project Partner: Hoffman Construction Company

Challenge: Shoring, Sheet Piling and Dewatering System

Overview: Condon-Johnson was contracted for the shoring and dewatering for underground concrete storage tanks. The scope of this project entailed the installation of secant piles, sheet piles, internal bracing, and the installation, operation and removal of a dewatering system.

Results: Condon-Johnson installed 20,827 square feet of shoring and dewatering for three excavations. There were 20 dewatering wells as a part of the dewatering system. The system produced a total of 2,700 to 3,800 gallons per hour.

Project Partner: Hoffman Construction Company

Challenge: Shoring, Sheet Piling and Dewatering System

Overview: Condon-Johnson was contracted for the shoring and dewatering for underground concrete storage tanks. The scope of this project entailed the installation of secant piles, sheet piles, internal bracing, and the installation, operation and removal of a dewatering system.

Results: Condon-Johnson installed 20,827 square feet of shoring and dewatering for three excavations. There were 20 dewatering wells as a part of the dewatering system. The system produced a total of 2,700 to 3,800 gallons per hour.

Block 5 – Park Tower

Location: San Francisco, CA

Project Partner: Clark Construction Group

Challenge: Installation of dewatering wells to fit the project’s needs and constraints.

Overview: Condon-Johnson was contracted to install the CIDH Piles and the internal bracing for the Park Tower as well the installation of dewatering wells.

Results: Because the jobsite was congested with 4 foot and 6 foot diameter shafts, the placement of the dewatering was crucial to the success of the project. Thirteen each 24 inch dewatering wells were strategically-placed throughout the congested site. One of the main challenges Condon-Johnson faced was installing the pumps and timers associated with the wells and ensuring that they turned on and off as the water level fluctuated. In addition, the large amount of excavators and Bobcats active on the site required daily monitoring of the wells to protect the integrity of the dewatering system.

Project Partner: Clark Construction Group

Challenge: Installation of dewatering wells to fit the project’s needs and constraints.

Overview: Condon-Johnson was contracted to install the CIDH Piles and the internal bracing for the Park Tower as well the installation of dewatering wells.

Results: Because the jobsite was congested with 4 foot and 6 foot diameter shafts, the placement of the dewatering was crucial to the success of the project. Thirteen each 24 inch dewatering wells were strategically-placed throughout the congested site. One of the main challenges Condon-Johnson faced was installing the pumps and timers associated with the wells and ensuring that they turned on and off as the water level fluctuated. In addition, the large amount of excavators and Bobcats active on the site required daily monitoring of the wells to protect the integrity of the dewatering system.

1314 Franklin Street

Location: Oakland, CA

Project Partner: Carmel Partners

Challenge: The installation of a perimeter auger cast soldier pile / lagging shoring system, site dewatering, and 400 each 18-inch diameter auger cast building support piles up to +140 feet in depth.

Overview: Condon-Johnson was contracted to install a large scope of work in a confined area with a very tight construction schedule.

Results: Condon-Johnson was able to successfully complete this project ahead of schedule by maintaining a positive working relationship with our project partner and utilizing our key people with the right equipment.

Project Partner: Carmel Partners

Challenge: The installation of a perimeter auger cast soldier pile / lagging shoring system, site dewatering, and 400 each 18-inch diameter auger cast building support piles up to +140 feet in depth.

Overview: Condon-Johnson was contracted to install a large scope of work in a confined area with a very tight construction schedule.

Results: Condon-Johnson was able to successfully complete this project ahead of schedule by maintaining a positive working relationship with our project partner and utilizing our key people with the right equipment.

Yellowstone Norris to Goldengate Phase 2

Project Partner: HK Contractors, Inc.

Challenge: Installing micropiles for new boardwalks on the edge of the Grand Canyon in Yellowstone National Park.

Overview: Condon-Johnson was contracted to install micropiles for the foundation support on three new boardwalks and also for the support of a failing retaining wall. The micropiles were located on the edge of the Grand Canyon which has an 800 foot drop off.

Results: Condon-Johnson was able to successfully overcome the very limited and technical access to install the micropiles. All personnel were tied off during the phasing of the work and the drill rig was winched down the slope to the edge of the cliff. The project was completed ahead of time and on budget.

Challenge: Installing micropiles for new boardwalks on the edge of the Grand Canyon in Yellowstone National Park.

Overview: Condon-Johnson was contracted to install micropiles for the foundation support on three new boardwalks and also for the support of a failing retaining wall. The micropiles were located on the edge of the Grand Canyon which has an 800 foot drop off.

Results: Condon-Johnson was able to successfully overcome the very limited and technical access to install the micropiles. All personnel were tied off during the phasing of the work and the drill rig was winched down the slope to the edge of the cliff. The project was completed ahead of time and on budget.

UPRR Harrisburg Truss Replacement

Location: Junction City, OR

Project Partner: Hamilton Construction Co.

Challenge: Installation of drilled shafts adjacent to an active railway bridge over the Willamette River without interrupting Union Pacific RR trains.

Overview: Condon-Johnson was contracted to install 7 foot diameter drilled shafts up to 200 feet in depth from a temporary work trestle. The new drilled shafts were adjacent and deeper than the existing bridge foundations which were still carrying the load of 20 to 24 trains per day.

Results: Condon-Johnson’s experienced personnel oscillated full depth temporary casing to safely and efficiently install the drilled shafts, which included 18 each 7 foot diameter drilled shafts ranging up to 149 feet in depth. The project was divided physically by the existing railroad bridge. Hamilton Contractors constructed a temporary work trestle on both sides of the existing bridge to provide access for Condon-Johnson’s service and dig cranes.

Project Partner: Hamilton Construction Co.

Challenge: Installation of drilled shafts adjacent to an active railway bridge over the Willamette River without interrupting Union Pacific RR trains.

Overview: Condon-Johnson was contracted to install 7 foot diameter drilled shafts up to 200 feet in depth from a temporary work trestle. The new drilled shafts were adjacent and deeper than the existing bridge foundations which were still carrying the load of 20 to 24 trains per day.

Results: Condon-Johnson’s experienced personnel oscillated full depth temporary casing to safely and efficiently install the drilled shafts, which included 18 each 7 foot diameter drilled shafts ranging up to 149 feet in depth. The project was divided physically by the existing railroad bridge. Hamilton Contractors constructed a temporary work trestle on both sides of the existing bridge to provide access for Condon-Johnson’s service and dig cranes.

Seattle BP Terminal Seawall Replacement

Location: Seattle, WA

Project Partner: Manson Construction Co.

Challenge: Installation of high capacity permanent tiebacks in sensitive material, while working over an active waterway inside a MARSEC Level 1 Controlled facility.

Overview: Condon-Johnson was contracted to install the permanent tieback anchors in a newly constructed bulkhead at the Seattle BP Fuel Terminal on the Duwamish Waterway in Seattle. Condon-Johnson was an active partner for years in the preconstruction phase of this project – providing a test program to better define soil properties, several rounds of budgeting, and constant input on the final design.

Results: Through the tireless efforts of the project team, the tiebacks were completed successfully and ahead of schedule. Additional thought and care was put into the drill spoil containment to limit contamination of the waterway. Condon-Johnson and Manson Construction worked side-by-side to develop methods of containing drill spoils and preventing any environmental issues. An added complication of the project was that the fuel terminal needed to remain operational during the construction of the new bulkhead, which forced Condon-Johnson to work within a very narrow pathway, approximately 12 feet wide between the seawall and a fence. The very narrow work area made coordination of crew and equipment paramount to complete the job safely and efficiently.

Condon-Johnson was contracted three years before the construction to perform a test program to test the feasibility of installing high capacity anchors in the soil. There was great concern about the achievable capacity in the very soft marine layers where the anchors were to be installed. The test program was a success and the data was used in the final design. The project team equipped with accurate full scale data, allowed the final anchors to be designed to the verge of geotechnical failure, which decreased project cost substantially.

Project Partner: Manson Construction Co.

Challenge: Installation of high capacity permanent tiebacks in sensitive material, while working over an active waterway inside a MARSEC Level 1 Controlled facility.

Overview: Condon-Johnson was contracted to install the permanent tieback anchors in a newly constructed bulkhead at the Seattle BP Fuel Terminal on the Duwamish Waterway in Seattle. Condon-Johnson was an active partner for years in the preconstruction phase of this project – providing a test program to better define soil properties, several rounds of budgeting, and constant input on the final design.

Results: Through the tireless efforts of the project team, the tiebacks were completed successfully and ahead of schedule. Additional thought and care was put into the drill spoil containment to limit contamination of the waterway. Condon-Johnson and Manson Construction worked side-by-side to develop methods of containing drill spoils and preventing any environmental issues. An added complication of the project was that the fuel terminal needed to remain operational during the construction of the new bulkhead, which forced Condon-Johnson to work within a very narrow pathway, approximately 12 feet wide between the seawall and a fence. The very narrow work area made coordination of crew and equipment paramount to complete the job safely and efficiently.

Condon-Johnson was contracted three years before the construction to perform a test program to test the feasibility of installing high capacity anchors in the soil. There was great concern about the achievable capacity in the very soft marine layers where the anchors were to be installed. The test program was a success and the data was used in the final design. The project team equipped with accurate full scale data, allowed the final anchors to be designed to the verge of geotechnical failure, which decreased project cost substantially.

Port of Juneau Cruise Ship Berths

Location: Juneau, AK

Project Partner: Manson Construction Co.

Challenge: Installation of extremely long, high capacity tiedown anchors and large diameter rock sockets in an unpredictable and severe marine environment.

Overview: Condon-Johnson was contracted to install 49 high capacity tiedown anchors for the construction of the new Juneau cruise ship facilities. All of the work was performed over the waters of the Gastineau Channel, off the coast of Juneau.

Results: Condon-Johnson, by working in close coordination with the project partner and owner, was able to complete all the tiedown anchors successfully, and was able to accelerate the project schedule. The tiedown anchors were installed inside pipe piles driven by Manson Construction to bedrock with depths of the pipe pile often in excess of 180 feet. Condon-Johnson then drilled 40 feet into the bedrock and installed the reinforcing bar; tiedown anchor lengths reached up to 250 feet depending on the bedrock quality and elevation. Each tiedown was load tested to 600,000 pounds, and post-tensioned to 500,000 pounds.

The project also called for six 48-inch diameter rock sockets, 20 feet into the bed rock that pipe piles would be driven into to fasten a floating pontoon dock. Condon-Johnson mobilized specialized crew and equipment, including a 48-inch diameter cluster hammer, to successfully complete the rock sockets. The rock sockets were challenging because the rock slope was very steep and near vertical at some socket locations. Further compounding the problems, all drilling occurred in the winter with an average high temperature of 15 degrees plus with wind speeds recorded up to 103 MPH.

Project Partner: Manson Construction Co.

Challenge: Installation of extremely long, high capacity tiedown anchors and large diameter rock sockets in an unpredictable and severe marine environment.

Overview: Condon-Johnson was contracted to install 49 high capacity tiedown anchors for the construction of the new Juneau cruise ship facilities. All of the work was performed over the waters of the Gastineau Channel, off the coast of Juneau.

Results: Condon-Johnson, by working in close coordination with the project partner and owner, was able to complete all the tiedown anchors successfully, and was able to accelerate the project schedule. The tiedown anchors were installed inside pipe piles driven by Manson Construction to bedrock with depths of the pipe pile often in excess of 180 feet. Condon-Johnson then drilled 40 feet into the bedrock and installed the reinforcing bar; tiedown anchor lengths reached up to 250 feet depending on the bedrock quality and elevation. Each tiedown was load tested to 600,000 pounds, and post-tensioned to 500,000 pounds.

The project also called for six 48-inch diameter rock sockets, 20 feet into the bed rock that pipe piles would be driven into to fasten a floating pontoon dock. Condon-Johnson mobilized specialized crew and equipment, including a 48-inch diameter cluster hammer, to successfully complete the rock sockets. The rock sockets were challenging because the rock slope was very steep and near vertical at some socket locations. Further compounding the problems, all drilling occurred in the winter with an average high temperature of 15 degrees plus with wind speeds recorded up to 103 MPH.

Mission Bay Block 3 East

Location: San Francisco, CA

Project Partner: Nibbi Brothers Construction

Challenge: Installation of 3 piece piles with confined access

Overview: Condon-Johnson was contracted to install the driven HP14x89 piles for a new veterans housing building in the Mission Bay District of San Francisco.

Results: Condon-Johnson’s key personnel successfully managed and installed 118 each three piece HP14x89 piling with lengths up to 265 feet, the longest in Mission Bay at the time. As one of the last lots for construction in Mission Bay, the project resulted in working within close proximity of housing and hospitals. This made daily night delivery of materials and strict work windows a critical factor in construction. Each pile was started by installing the first piece with an ABI TM25M to ensure location and assess obstructions in the upper fill. After splicing, both the second and third section of piling were installed using a D62-22 diesel impact hammer.

Project Partner: Nibbi Brothers Construction

Challenge: Installation of 3 piece piles with confined access

Overview: Condon-Johnson was contracted to install the driven HP14x89 piles for a new veterans housing building in the Mission Bay District of San Francisco.

Results: Condon-Johnson’s key personnel successfully managed and installed 118 each three piece HP14x89 piling with lengths up to 265 feet, the longest in Mission Bay at the time. As one of the last lots for construction in Mission Bay, the project resulted in working within close proximity of housing and hospitals. This made daily night delivery of materials and strict work windows a critical factor in construction. Each pile was started by installing the first piece with an ABI TM25M to ensure location and assess obstructions in the upper fill. After splicing, both the second and third section of piling were installed using a D62-22 diesel impact hammer.

© Condon-Johnson & Associates • 480 Roland Way, Suite 200, Oakland, CA 94621 • 510-636-2100 • Site By Bridges